Energy Projects

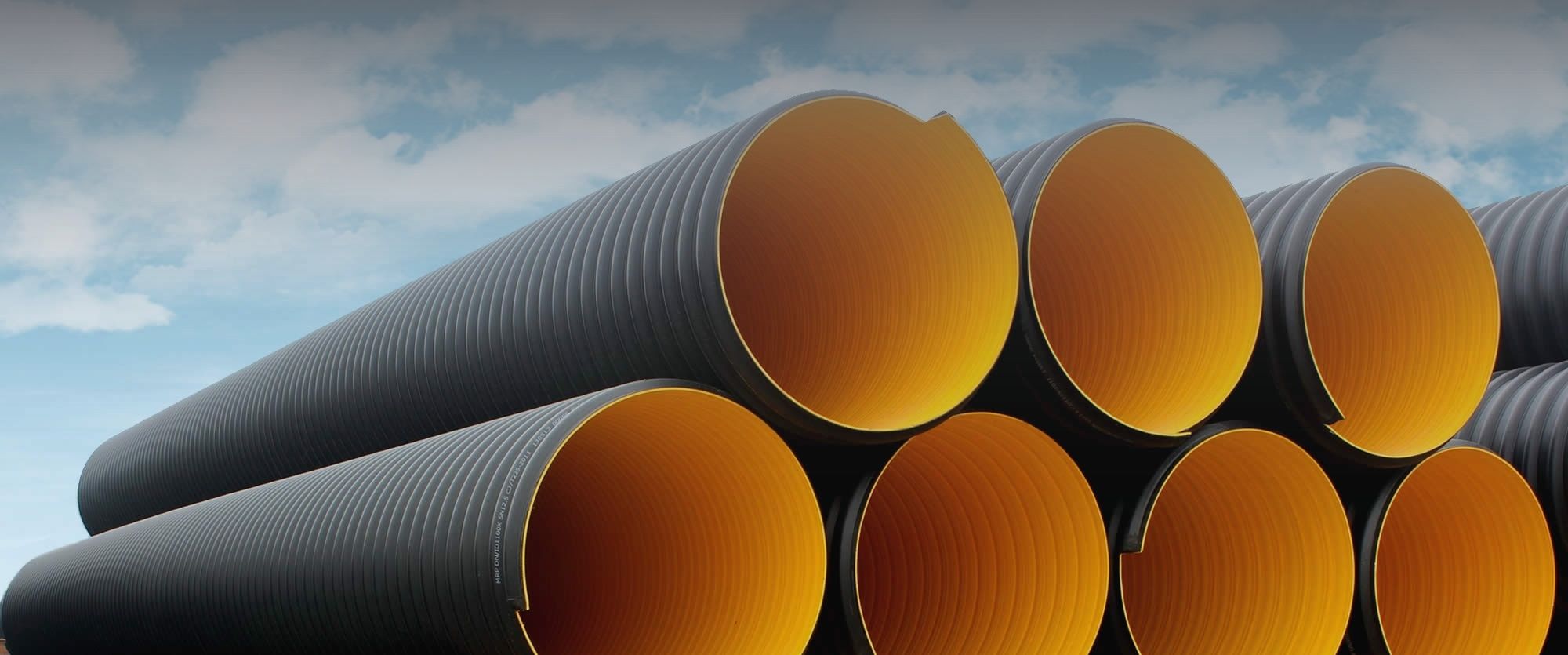

High Performance Pipe Systems for the Energy Sector

In energy production plants, infrastructure systems play a critical role in the efficiency, continuity, and safety of operations. At Kuzeyboru, with our PE 100 and GRP pipe systems, we successfully provide high-pressure resistance, chemical resistance, and long-lasting infrastructure solutions for many energy projects across Turkey.

In hydroelectric power plants (HPP), solar energy plants (SSP), thermal and geothermal power plants, biogas/biomass facilities, and industrial energy production sites, our products are actively used in the following lines:

- Cooling water circulation lines,

- Rainwater and wastewater discharge lines,

- Chemical solution transfer systems,

- SSP site panel cable protection and rainwater drainage,

- Geothermal liquid transport and reinjection lines.

Durable and efficient infrastructure solutions for the energy sector

In energy production plants, infrastructure systems play a critical role in the efficiency, continuity, and safety of operations. At Kuzeyboru, with our PE 100 and GRP pipe systems, we successfully provide high-pressure resistance, chemical resistance, and long-lasting infrastructure solutions for many energy projects across Turkey.

In hydroelectric power plants (HPP), solar energy plants (SSP), thermal and geothermal power plants, biogas/biomass facilities, and industrial energy production sites, our products are actively used in the following lines:

- Cooling water circulation lines,

- Rainwater and wastewater discharge lines,

- Chemical solution transfer systems,

- SSP site panel cable protection and rainwater drainage,

- Geothermal liquid transport and reinjection lines.

Our PE 100 pipes offer maximum efficiency in field applications with their flexible structure, welding capability, and durability in external environments.

Our CTP pipes are provided for projects with high temperature and chemical resistance requirements, offering special internal coatings and rigidity class options.

All our products are tested in our accredited test centers in compliance with TSE and ISO standards before being shipped to the site. Each project receives specific planning for diameter, wall thickness, connection type, and shipment scheduling, with technical documentation and on-site support provided.

Our production facilities in Aksaray and Malatya offer fast and planned responses to energy projects’ typically tight schedules. Whether it’s high-volume field piping or short-distance technical line applications, we offer solution-oriented approaches for every project.

As Kuzeyboru, we not only provide products but also expertise and sustainability in infrastructure projects contributing to Turkey’s energy transformation.