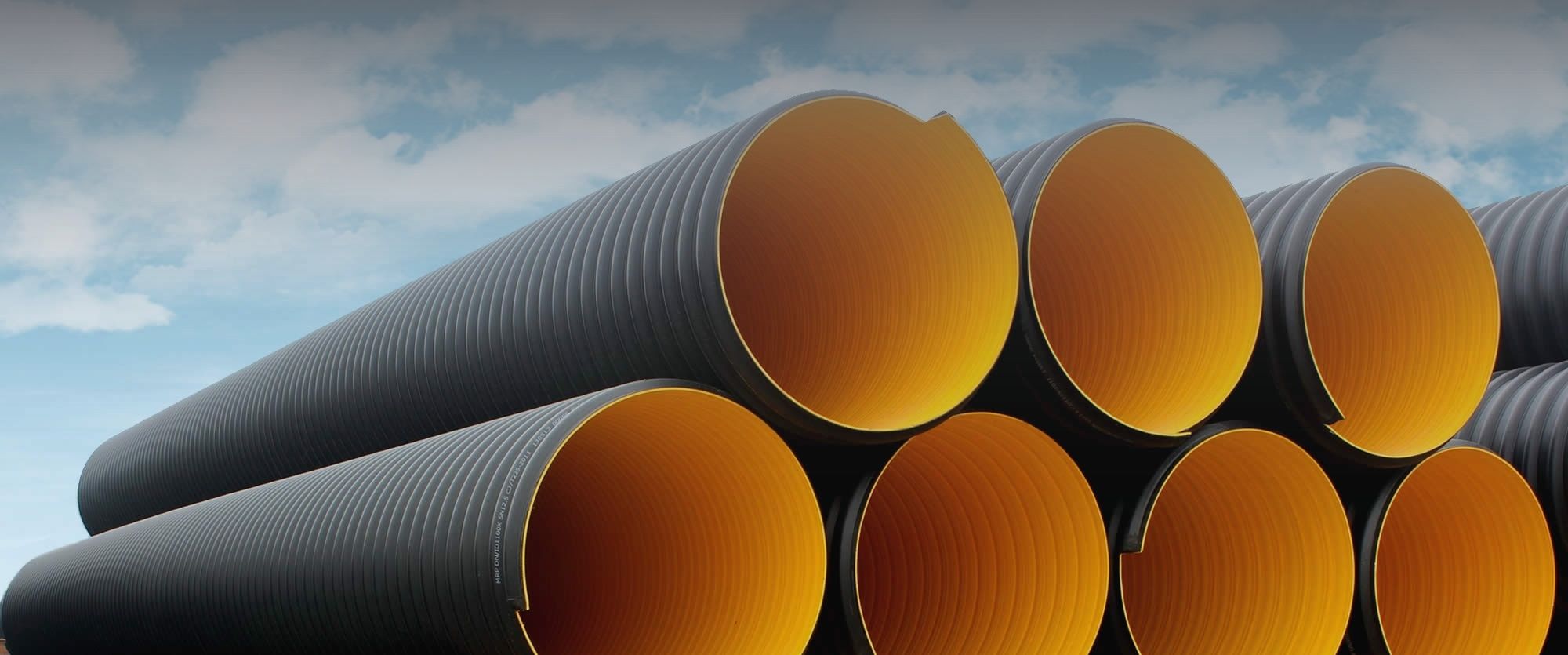

Next-Generation Polyethylene Pipe Solutions for Strength and Efficiency

Kuzeyboru polyethylene pipes are manufactured with superior quality and high performance in diameters ranging from 20 mm to 1600 mm and pressure classes from PN4 to PN32, customized to meet project-specific diameter, pressure, and dimensional requirements.

Our Polyethylene (HDPE) Product Range

Kuzeyboru PE Pipe Systems are manufactured from polyethylene (PE) raw material in accordance with TS EN 12201-1 and TS EN 12201-2 standards. Production covers the full range of pressure classes, including:

SDR41–PN4, SDR33–PN5, SDR26–PN6, SDR21–PN8, SDR17–PN10, SDR13.6–PN12.5, SDR11–PN16, SDR9–PN20, SDR7.4–PN25, and SDR6–PN32, in diameters from 20 mm to 1600 mm.

Pipes up to Ø125 mm are supplied in coil form, while those with diameters ≥ Ø125 mm are produced in straight lengths of 13.5 meters. Upon request, pipe color, length, marking, and packaging can be customized to meet project requirements.

Click here for detailed information on HDPE pipe diameters

The History of Polyethylene

Polyethylene was accidentally discovered in 1933 and quickly became an integral material in modern industry. The first commercialized polyethylene product was low-density polyethylene (PE-32 LDPE), produced through free radical polymerization.

Subsequent developments introduced new polymerization techniques based on chromium and Ziegler-Natta catalysts, enabling the creation of PE 63, which could be used in systems that did not require high-pressure conditions.

Generations of Polyethylene Materials

- 1st Generation: PE 32 (LDPE), PE 40 (LDPE), PE 63 (HDPE Pipes)

- 2nd Generation: PE 80 (MDPE), PE 80 (HDPE Pipes)

- 3rd Generation: PE 100 (HDPE Pipes)

The evolution of polyethylene has enabled enhanced mechanical performance and cost-efficiency. PE 100, developed in the late 1990s, has become the industry standard, offering greater pressure resistance with reduced wall thickness, making it ideal for potable water, utility water, and natural gas distribution networks.

Raw Material of Polyethylene

Polyethylene is a thermoplastic polymer derived from the monomer ethylene (C₂H₄). It consists of two CH₂ groups connected by a double bond (CH₂=CH₂). Through polymerization, these monomers form long molecular chains, resulting in polyethylene — commonly referred to as PE in the plastics industry.

Technical Properties of Polyethylene Pipes

The compound used must be selected according to the type of polyethylene material. Raw materials for pipe and fitting production are classified by their Minimum Required Strength (MRS), which indicates the pipe’s strength under internal pressure over a period of 50 years at 20°C.

All material selections must meet MRS performance tables when tested in pipe form.

Material Design and Maximum Allowable Design Stress

All calculations in PE pipe systems are based on the classification of the raw material and the network conditions, using an appropriate design (safety) coefficient (C):

- Natural Gas Networks: C = 2.0

- Potable Water Transmission Lines: C = 1.25

These coefficients are applied to determine design stress and ensure the long-term safety and performance of the system.