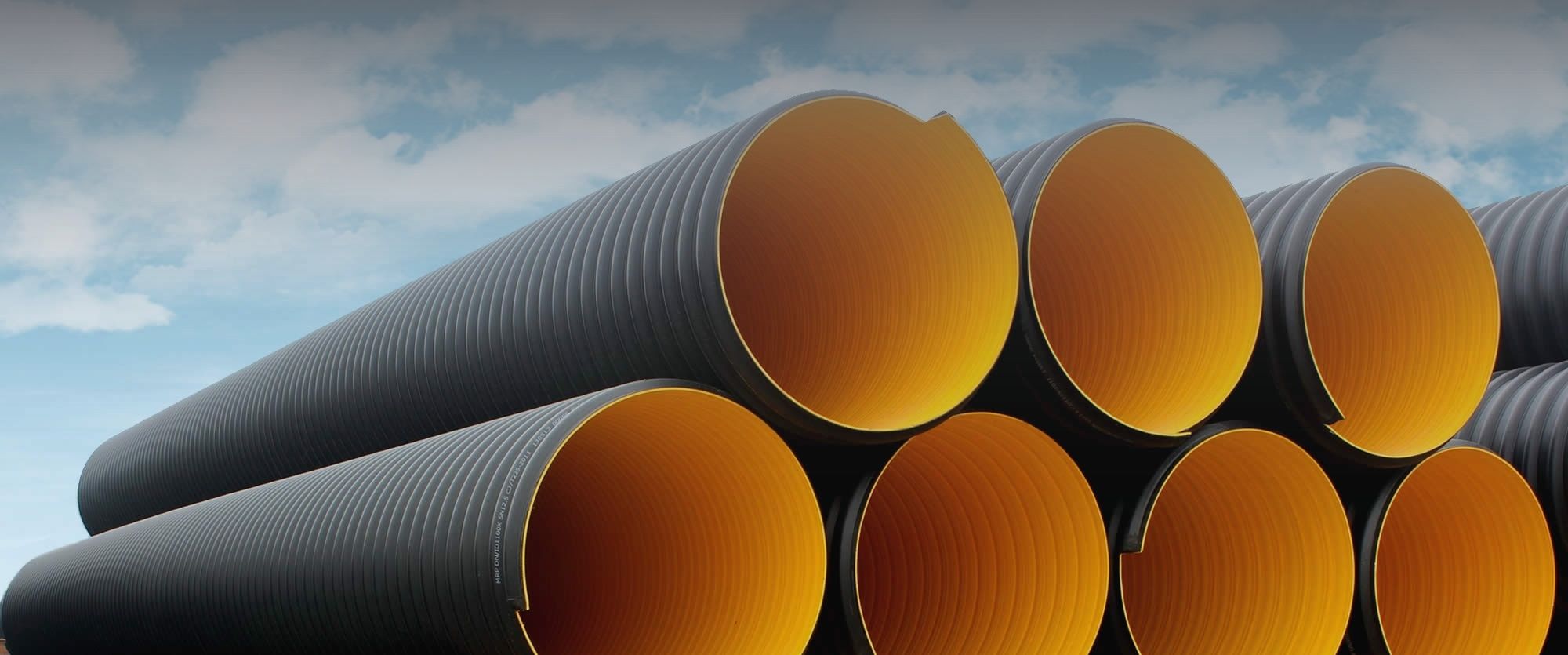

Pipes

Kuzeyboru pre-insulated pipes are manufactured in accordance with international standards (TS EN 253, TS EN 448, TS EN 12201-2+A1), offering high quality and user convenience. Developed using the latest technology, these pipes minimize heat loss to enhance energy efficiency while providing long-lasting and durable performance.

Reliable and Efficient Thermal Insulation

The polyurethane foam used between the carrier pipe and the outer casing absorbs thermal expansion stresses and transfers friction forces between the soil and the pipe to the carrier pipe. This eliminates the need for additional expansion compensators, resulting in a more efficient and cost-effective infrastructure solution.

Widely used in geothermal energy systems, hot water distribution lines, industrial facilities, and the marine industry, Kuzeyboru pre-insulated geothermal pipes deliver reliable performance with their high strength and superior insulation properties.

- High-Density Polyethylene (HDPE) Carrier Pipe: Offers excellent resistance to abrasion and chemicals.

- Polyurethane Foam Insulation: Thermal conductivity coefficient at 50°C is <0.026 W/(mK), providing outstanding heat retention.

- Protective Outer Casing: Made from high-density polyethylene, it ensures superior resistance to impact and external factors.

- Waterproof Closed-Cell Structure: Prevents water ingress for extended service life.

- High Thermal Resistance: Continuous operating temperature up to 120°C, with peak resistance up to 140°C.

- Compliance with TS EN 253 Standard: Foam core density ≥ 60 kg/m³, overall density ≥ 80 kg/m³, providing excellent mechanical strength through high compression and shear resistance.

- Heat Loss Rate: Just 1°C over 20 km, indicating high insulation performance.

Kuzeyboru pre-insulated geothermal pipes are the ideal solution for energy-efficient projects requiring durability, excellent thermal insulation, and long service life.

Applications of Pre-Insulated Pipes

Thanks to their high thermal insulation and durable structure, pre-insulated pipes are safely used in various sectors, including:

- Geothermal district heating and cooling networks

- Fire lines and safety systems

- Central heating systems (residential complexes, satellite towns)

- Underground and gallery-type installations

- Industrial facilities and production lines

- Greenhouse and agricultural irrigation systems

- Gas and petroleum pipelines

- Hotels and tourism facilities

- University campuses and military installations

- Shipbuilding and maritime applications

- Water supply lines and infrastructure projects

Shipbuilding requires piping systems that can withstand harsh environmental conditions such as saltwater, high humidity, strong winds, and temperature fluctuations. Kuzeyboru pre-insulated pipes are specially designed to deliver maximum performance and longevity in such marine environments.

These systems are ideal not only for new shipbuilding projects but also for the renovation of existing pipelines. Thanks to geothermal pipe technology, they offer resistance to high pressure and temperature variations while maintaining excellent flow efficiency due to their insulation structure.

Advantages in Ship Applications

- Resistant to saltwater and humidity; offers corrosion protection.

- Withstands high pressure and temperature; ensures long service life.

- Provides energy efficiency by minimizing heat loss.

- Lightweight and flexible design allows easy installation.

- Meets the high safety standards of the maritime sector.

Pre-insulated geothermal pipes are among the most reliable and durable solutions used extensively in shipboard installations. Contact our expert team to find the most suitable solution for your marine projects.

- Superior thermal insulation reduces energy loss and enhances system efficiency.

- Excellent resistance to acids, alkalis, and various chemicals—ideal for industrial use.

- UV-resistant for long-lasting outdoor applications.

- HDPE outer casing protects the inner pipe from corrosion and rust.

- Lightweight and flexible design enables fast and easy installation, reducing labor costs.

- Minimal maintenance requirements translate into long-term cost savings.

- Offers a service life of over 50 years, ensuring reliability in infrastructure systems.

Pre-insulated pipe sizes vary depending on the application, including geothermal systems, district heating, industrial installations, and infrastructure projects. Typically ranging from 20 mm to 1200 mm in diameter, these pipes are engineered to deliver high performance for hot water, steam, gas, and chemical transport.

The inner carrier pipe diameter is selected based on flow requirements, while the insulation thickness and outer casing diameter are optimized to minimize heat loss. Custom diameter options allow projects to achieve maximum energy savings with lower operating costs.

With a temperature resistance up to +120°C, Kuzeyboru pre-insulated pipes offer a wide range of application possibilities. For proper pipe and insulation thickness selection, consult our experts to find the most efficient solution for your project.

Pre-insulated pipe prices vary depending on diameter, insulation thickness, material specifications, and application area. Used across a broad spectrum of geothermal systems, district heating lines, industrial facilities, and infrastructure projects, these pipes provide long-term cost advantages due to their durability and energy efficiency.

Prices are determined by project-specific requirements and technical preferences. With polyurethane foam insulation that minimizes heat loss, corrosion-resistant HDPE casings, and various temperature resistance options, Kuzeyboru pre-insulated pipes enhance energy efficiency while reducing operational costs.

For the most up-to-date pricing and tailored offers, contact us to receive detailed information. Kuzeyboru pre-insulated pipes, produced to high quality standards, offer dependable and long-lasting solutions for your energy infrastructure needs.

An insulated pipe is a type of piping covered with special thermal insulation material to prevent heat loss and protect the pipe from external influences. Commonly used in central heating systems, geothermal energy projects, and industrial facilities.

Geothermal pipes are used to transport hot water in geothermal power plants, district heating networks, central hot water systems, greenhouses, and industrial applications.

Pre-insulated geothermal pipes, pre-insulated steel pipes, and high-temperature resistant PPRC or HDPE pipes are used. These ensure minimal heat loss due to their thermal insulation and temperature resistance.

Thanks to their resistance to heat and pressure, pre-insulated geothermal pipes have a service life of over 50 years. The insulating layer enhances durability and ensures long-term energy efficiency.

Pre-insulated steel pipes can continuously operate at 120°C and endure peak temperatures up to 140°C for short durations.

They consist of three layers: the carrier pipe (HDPE or steel), the insulation layer (polyurethane foam), and the outer casing (HDPE or metal sheathing).

Insulation thickness depends on the pipe’s diameter and the temperature of the transported fluid. Typically, polyurethane foam insulation ranges between 20 mm and 100 mm.

The outer casing protects the pipe from impacts, chemicals, and UV radiation. Made from HDPE or metal, it ensures a long service life for the pipe.

By minimizing heat loss, insulated pipes improve energy efficiency, reduce operational costs, and support sustainable energy usage.