PE100 Pressure Drinking

Water Pipes

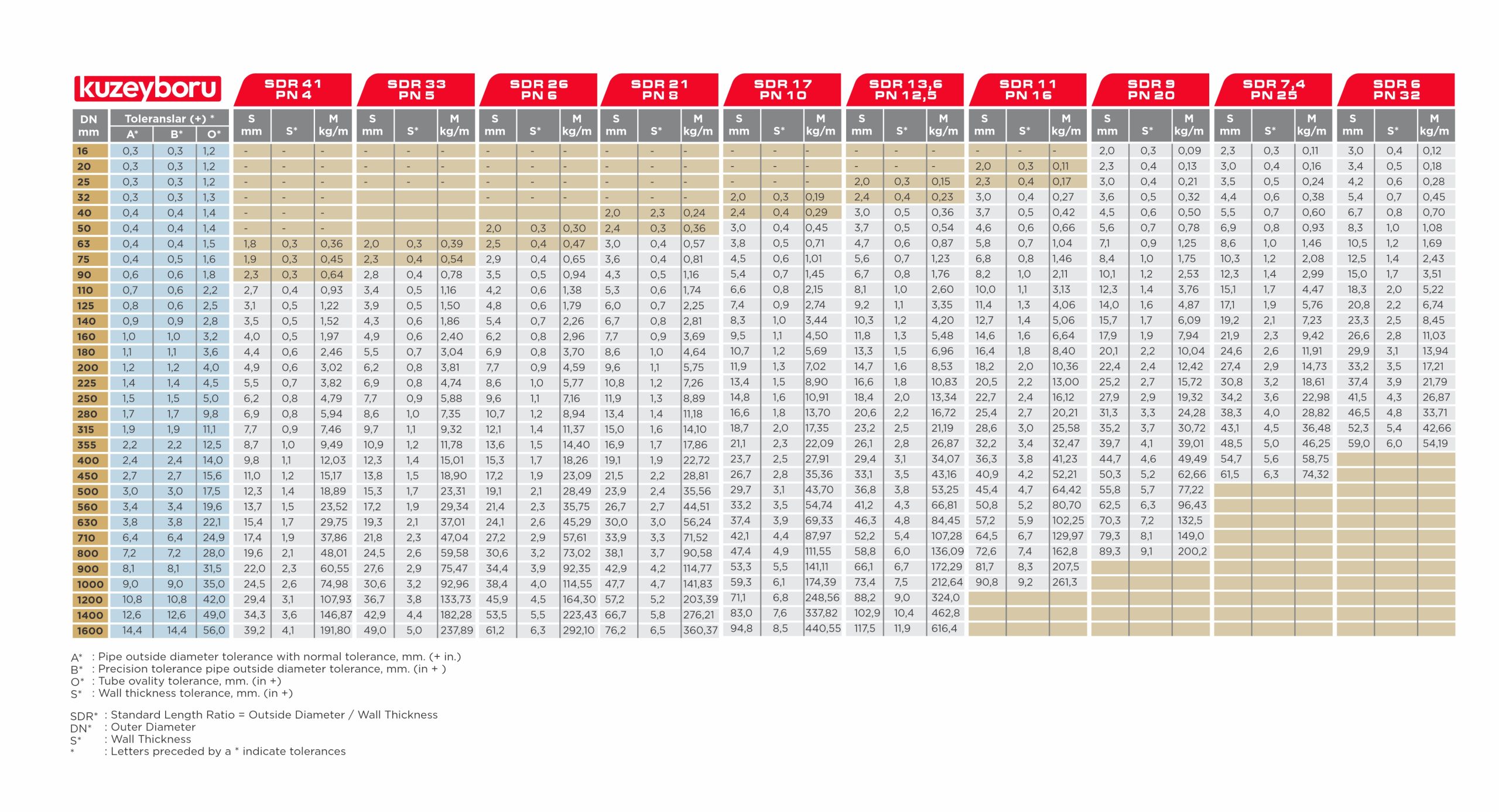

Kuzeyboru PE Pipe Systems are manufactured from polyethylene (PE) raw material in compliance with TS EN 12201-1 and TS EN 12201-2 standards. Production covers pressure classes SDR41–PN4, SDR33–PN5, SDR26–PN6, SDR21–PN8, SDR17–PN10, SDR13.6–PN12.5, SDR11–PN16, SDR9–PN20, SDR7.4–PN25, and SDR6–PN32, with diameters ranging from 20 mm to 1600 mm.

PE pipes are produced in coil form up to Ø125 mm, and in custom lengths for Ø125 mm and above. Pipe color, length, marking, and packaging can be customized upon request.

With Kuzeyboru, Your Infrastructure is in Safe Hands!

Kuzeyboru PE100 pipe systems are the ideal choice for long-lasting and reliable infrastructure. With their strength, eco-friendly structure, and customizable production options tailored to project requirements, we continue to be the professional solution partner in the sector. Our polyethylene pipes support our commitment to environmental responsibility with their recyclability even after years of use, contributing to a sustainable future.

We design our HDPE pipes to deliver high performance even under challenging terrain conditions. Thanks to their lightweight structure, they are easy to transport and allow for fast and hassle-free installation even in icy, muddy, or swampy areas. We develop solutions that can be safely used in all kinds of field conditions. Made from high-density polyethylene, our HDPE pipes offer excellent resistance to corrosive environments such as saltwater, sanitary waste, and chemical-laden fluids. Their non-corrosive nature provides low-maintenance infrastructure solutions that last for decades.

Combining a strong R&D foundation with innovative production technologies, Kuzeyboru manufactures HDPE pipes to the highest quality standards. With essential features such as leak-tightness, durability, and flexibility, we ensure the safety of your infrastructure systems.

Technical Features of Polyethylene (HDPE) Pipes

At Kuzeyboru, we closely follow industry developments and continuously conduct research in our quality laboratories. Our HDPE pipes, ranging from 20 mm to 1600 mm, are manufactured using the latest technology and highest quality standards.

Thanks to the superior properties of polyethylene, it stands out as one of the best alternatives for pressurized clean water systems. HDPE pipes are widely used in underground and aboveground water networks, marine outfall projects, fish farming cages, and barrier construction.

Key Features of Polyethylene Pipes:

- Excellent resistance to corrosion, chemicals, and impacts

- 100% leak-tightness through welded joints

- Service life of 50 years or more under nominal pressure

- Maintains elasticity and resists cracking down to -50°C

- Available in pressure classes from SDR6–PN32 to SDR41–PN4

- Recyclable and environmentally friendly

- Suitable for a wide range of applications such as drinking water networks, marine outfalls, fish farms, and agricultural irrigation systems

- Can be installed in long lengths onshore and then floated into position, even under harsh marine and terrain conditions

- Certified according to TS EN 12201, ISO 4427, and other international quality standards

Kuzeyboru HDPE pipes (High-Density Polyethylene Pipes) offer a lightweight, durable, and high-performance fluid transport solution, featuring a smooth inner and outer surface structure. Thanks to the advanced production technologies developed in our R&D center and our lean manufacturing principles, our HDPE pipes are designed to be transported with minimal heavy equipment and easily installed even under the most challenging site conditions. From icy terrains to marshlands, our systems ensure reliable performance in every environment.

With our commitment to sustainable production, we utilize recyclable materials that minimize environmental impact. We monitor every stage of production through digital systems and fully implement quality, environmental, and safety standards—providing infrastructure solutions that meet not only today’s needs but also the demands of the future.

Advantages of HDPE Pipes

- High flow efficiency with minimal friction loss

- Lightweight and easy to transport, requiring minimal heavy machinery

- Applicable even in harsh conditions such as ice, wetlands, rocky, thorny, and muddy terrain

- Corrosion-free and long-lasting

- Excellent resistance to saltwater, sewage, acids, and alkalis

- High impact strength and resistance to sudden pressure changes

- Manufactured from recyclable materials

- Requires minimal maintenance due to its chemical and environmental durability

The weight of Kuzeyboru HDPE pipes, also known as HDPE pipes, is calculated based on the volume of a hollow cylinder multiplied by the density of the HDPE material. Since the pipes undergo thermal processing during production, they exhibit expansion characteristics. Therefore, when preparing HDPE pipe dimension tables, tolerance values must also be considered.

HDPE Pipe Diameter Chart

Kuzeyboru HDPE pipes are manufactured in a wide range of diameters from 20 mm to 1600 mm, available in various pressure classes (PN). Depending on the application, our product portfolio includes models with thin wall thickness for low-pressure systems and thicker-walled models designed to withstand higher pressures.

PE80 Natural Gas Pipes

HDPE natural gas pipes are engineered for maximum durability against high pressure and external impacts. These pipes deliver exceptional leak-tightness and safety, offering long-lasting, reliable performance in gas distribution lines. Their flexibility ensures easy installation even in rough terrain. Produced in accordance with international certifications, Kuzeyboru PE80 natural gas pipes are the ideal solution for secure and efficient gas transportation. Click here for more details about our PE80 Natural Gas Pipes.

HDPE Dredging Pipes

HDPE dredging pipes are used for transporting sludge, sand, and sediments from the seabed, lakebed, or riverbed. Their high abrasion resistance and flexibility make them ideal for harsh underwater conditions. Resistant to chemicals and saltwater, they are lightweight and easy to transport, making them a top choice for marine and dredging projects. Please click here for detailed information about our dredging pipes.

HDPE Drainage Pipes

Used in agricultural areas, highways, airports, and building foundations, HDPE drainage pipes efficiently collect and channel excess water with their high permeability. These pipes are resistant to environmental impacts and chemicals, offering long service life with virtually no maintenance requirements. Their flexible and lightweight design allows for quick and easy installation.Please click here for detailed information about our drainage pipes.

HDPE Pre-Insulated Pipes

HDPE pre-insulated pipes provide high energy efficiency in heating, cooling, and geothermal systems. The insulation layer minimizes heat loss, enabling greater energy savings and system efficiency. Their waterproof and UV-resistant outer layer offers additional protection against environmental conditions. These long-lasting, low-maintenance pipes are suitable for applications ranging from industrial facilities to residential projects.Please click here for detailed information about our pre-insulated pipes.

HDPE Pipe Price List

HDPE pipe prices vary based on diameter, pressure class (PN), wall thickness, and intended application. Widely used in systems such as potable water supply, agricultural irrigation, natural gas lines, sewer systems, and general infrastructure, Kuzeyboru HDPE pipes stand out with their flexibility, durability, and long service life.

Manufactured from high-density polyethylene (PE100), Kuzeyboru HDPE pipes provide leak-tightness, corrosion resistance, and easy installation, making them a reliable choice for infrastructure projects. Available in a wide range of diameters and pressure ratings, our products offer both technical performance and cost efficiency.

To get a project-specific price quote and access our current HDPE pipe price list, please contact us.

With our 162,336 m² production facility, Kuzeyboru continues to set itself apart in the infrastructure sector. Equipped with state-of-the-art manufacturing lines, high-capacity automation systems, and advanced technology, we constantly strengthen our competitive edge in local and international markets.

We manage not only production but also engineering, design, quality control, and logistics processes in an integrated manner. Each product is manufactured to the highest standards, offering durable, long-lasting, and environmentally friendly solutions.

Our manufacturing philosophy is built on flexibility and customization. With a customer-focused approach, we tailor solutions to the needs of various sectors and specific project requirements. Our smart automation systems maximize efficiency and quality while minimizing human error.

Backed by a robust R&D infrastructure and a vision focused on continuous improvement, we are ready to meet the infrastructure needs of both today and the future. Preferred in thousands of projects worldwide, we stand out with our reliability and sustainable practices.

We produce high-pressure HDPE pipes using advanced manufacturing systems and high-density polyethylene (PE100) raw materials. With 20 production lines and a daily output of 250 tons, we offer a wide product range from 20 mm to 1600 mm in diameter and PN4 to PN32 pressure classes.

Thanks to our customer-centric approach, we can customize pipe color, length, marking, and packaging according to project needs. Automated feeding systems minimize staff contact with raw materials, enhancing safety and cleanliness.

With our proprietary infrastructure monitoring technology, we track raw material silos, water temperature and pressure levels, chiller systems, and water pump performance in real time enabling us to manage production with maximum efficiency.

At Kuzeyboru, every stage of production is digitally monitored to ensure consistent quality and traceability. Each product is labeled with a unique lot number, allowing full tracking from production to shipment. This includes raw material origin, supplier details, cost, production batch, quality test records, and final customer information ensuring both transparency and quality assurance.

Our pipe geolocation system allows us to pinpoint pipe positions on-site to the nearest meter, simplifying maintenance, repair, and infrastructure upgrades while saving time and cost.

Environmentally conscious in logistics as well, we use nested pipe shipping methods to reduce transport costs and minimize our carbon footprint.

Kuzeyboru offers a wide range of HDPE electrofusion (EF) and butt-weld (spigot) fittings, ensuring secure, leak-proof, and long-lasting connections in PE piping systems. Each fitting undergoes rigorous quality testing before shipment. Designed for ergonomic handling and easy installation, they offer fast on-site application, reducing labor time and cost. The electrofusion system provides a key advantage in confined spaces. Resistant to high pressure and harsh environmental conditions, Kuzeyboru fittings are the reliable choice for critical infrastructure connections.

- Leak-proof, secure fusion bonding

- Service life of up to 50 years

- Low maintenance requirements

- High efficiency with minimal labor

- Compliance with international standards.

HDPE pipes and fittings offer reliable performance under high pressure and long service life across a variety of applications. They are joined using thermal fusion or mechanical connectors to ensure a leak-proof, robust system. Pipes made from different materials can also be integrated using flanges, compression fittings, and transition adapters. Choosing the right joining method is essential for optimal performance and durability.

Common HDPE Pipe Joining Methods:

- Electrofusion (EF) Welding

- Butt Welding

- Coupler (Mechanical) Joining

Electrofusion (EF) Welding

This is the preferred method for high-pressure and precise connections. Electrical resistance wires within the EF fitting heat and fuse the pipe ends.

- Suitable for pipe diameters from 20 mm to 1600 mm

- Quick and reliable installation

- Ideal for narrow trench projects

- High pressure resistance and long service life

Butt Welding

One of the most common methods for joining HDPE pipes and fittings. Pipe ends are shaved, then joined under heat and controlled pressure.

- Applicable for pipes up to 1600 mm

- Creates strong, leak-proof joints

- Allows direct pipe joining without fittings

- Preferred in long-life infrastructure projects

Coupler Joining

This mechanical method is ideal where welding isn’t feasible. Pipes are joined using mechanical couplings tightened into place.

- Ideal for fast installation

- No special tools required

- Reliable solution for small diameter pipes

At Kuzeyboru, we apply the highest standards of quality and safety in all HDPE pipe joining methods—offering durable, leak-free systems for your projects. Select the most suitable method to build efficient and secure infrastructure solutions.