Testing Laboratory

Turkey’s Largest and Most Advanced Testing Center

A Fully Equipped

3,000 m² Test Facility

We meticulously test our products in accordance with established standards. Since 2018, we have been conducting durability and safety tests at our laboratories in Aksaray and Malatya—some of the largest accredited test centers in Turkey.

In this extensive 3,000 m² facility, we collaborate with our R&D department to thoroughly inspect each product.

We record all test results digitally using custom-developed software, ensuring quality is backed by data.

Product Groups Tested:Product Groups Tested:

- HDPE Pipes

- HDPE-RC (Crack Resistant) Pipes

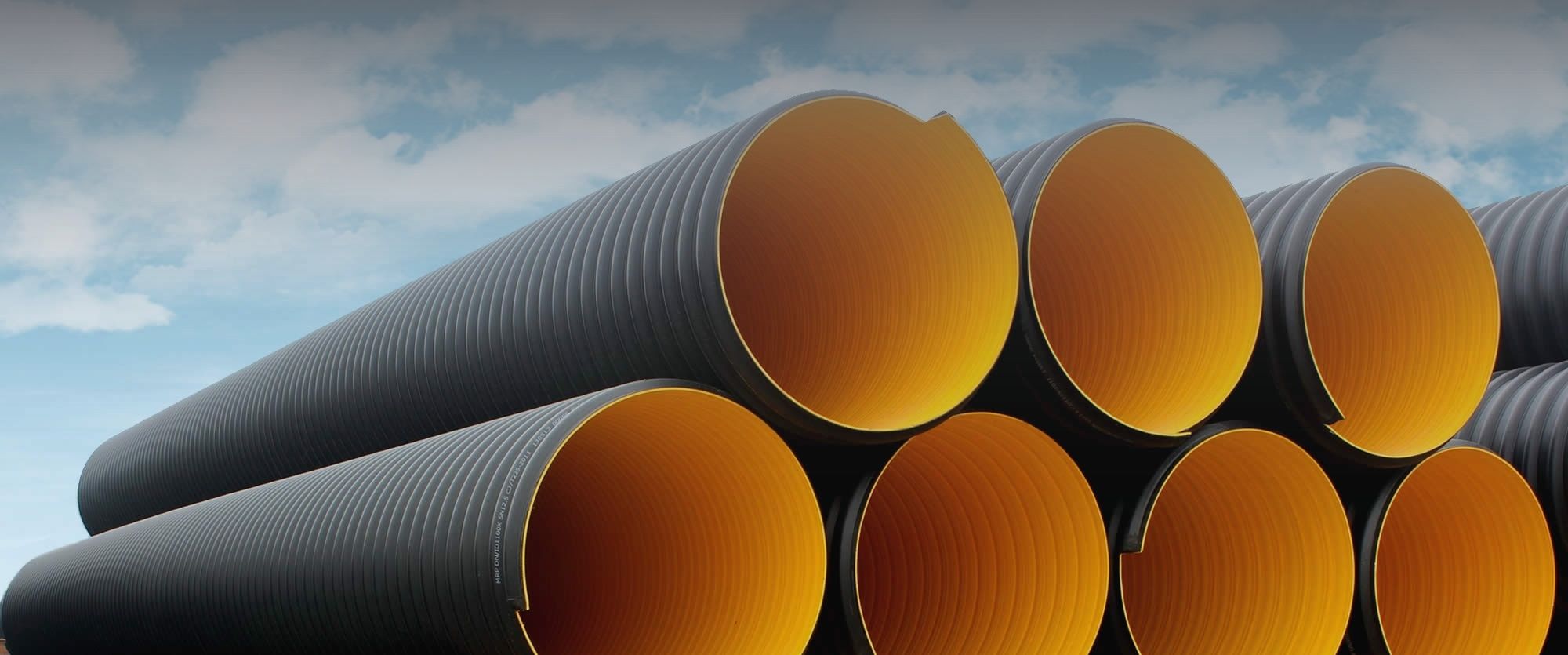

- Corrugated and Steel-Reinforced Spiral Pipes

- Natural Gas Pipes

- PP-R Pipes and Fittings

- PP-RC Composite Pipes

- PE-X and PE-RT Pipes

At our Aksaray production facility, Kuzeyboru operates one of the country’s most advanced pressure testing infrastructures.

Equipped with four large hydrostatic pressure tanks, our lab can simultaneously test 30 different samples at 60°C, 80°C, and 95°C. This makes our system one of the fastest and most comprehensive pressure testing setups in Turkey. These processes help us certify the durability, strength, and quality compliance of our products.

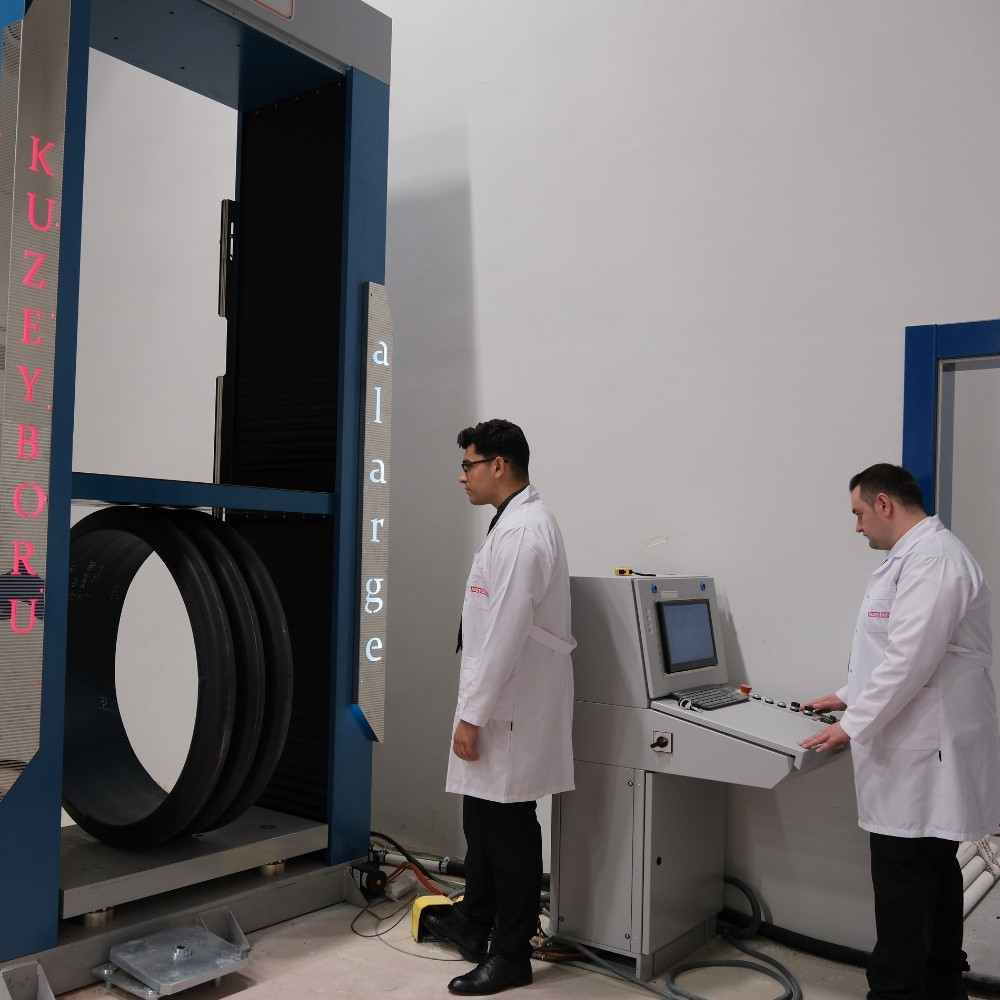

Ring Stiffness and Flexibility Testing up to Ø2400 mm

By enhancing our lab capabilities, we now conduct ring stiffness and flexibility tests on plastic pipes up to Ø2400 mm in diameter—making us the first and only facility in Turkey with this capacity.

This allows us to:

- Ensure reliable results in large-diameter pipes,

- Deliver tailored solutions for customer-specific needs,

- Conduct all quality control tests in accordance with international standards.

Include:

- Resistance to Internal Pressure (TS EN ISO 1167)

- Tensile Strength (TS EN ISO 6259)

- Resistance to Rapid Crack Propagation (ISO 13477 / 13478)

- Ring Stiffness (TS EN ISO 9969)

- Ring Flexibility (ISO 13968)

- Environmental Stress Crack Resistance

- Longitudinal Reversion (Thermal Elongation

- Dimensional Measurement (TS EN ISO 3126)

- Melt Flow Rate (TS EN ISO 1133)

- Density (TS EN ISO 1183)

- Oxidation Induction Time (TS EN ISO 11357-6)

- Volatile Content Measurement

- Carbon Black Content and Dispersion (ISO 6964)t

Our CTP (Glass Reinforced Plastic) production facility in Malatya reflects our commitment to engineering, quality, and sustainability—not just pipe production.

Every pipe produced here undergoes rigorous testing under extreme conditions:

- Exposed to temperature stress

- Tested for high-pressure resistance

- Examined for chemical durability

- Evaluated for long-term performance in humid environments

Tested in compliance with international standards such as TS ISO 1071, 7509, 10952, and 10468, we offer more than just pipes—we deliver longevity, trust, and quality.

Our Malatya facility is not only a manufacturing site but also a certified point of trust, where resilience is both tested and proven.

Here, product and raw material tests are executed with precision using advanced lab equipment, international test methods, and expert technical staff.

- Device: Barcol Hardness Tester

- Standard: TS EN 59

- Purpose: To determine the surface hardness of the materia

- Standard: TS ISO 10466

- Capacity: Max 300 kN

- Purpose: To measure resistance to ring deformation

- Standard: TS ISO 8521 – Method D

- Purpose: To assess resistance to external loads

- Standard: TS ISO 8513

- Capacity: Max 300 kN

- Purpose: To determine axial tensile resistance

- Standard: ISO 7511

- Purpose: To check the sealing performance of joints under pressure

- Standard: TS ISO 7685 – Method B

- Scope: Max d = 4000 mm

- Purpose: To determine ring stiffness

- Standard: TS EN ISO 3126

- Parameters: Pipe length, outer diameter, wall thickness

1. Resin Tests

Resin quality in GRP pipe production plays a critical role in overall product performance. Regularly conducted resin tests include:

Viscosity Test

- Purpose: Assess fluidity

- Significance: Affects saturation and fiber absorption during production

Gel Time Measurement

- Purpose: Determine solidification time

- Significance: Ensures controlled curing and process stability

Peak Time Measurement

- Purpose: Identify maximum heat during chemical reaction

- Significance: Used to validate curing profile and production compatibility

Solids Content (%)

- Purpose: Measure actual polymer content

- Significance: Directly impacts final mechanical strength

2. Glass Fiber Tests

Fiber quality directly affects mechanical performance and product longevity. The following tests are routinely conducted:

Visual Inspection

- Purpose: Detect deformations, cracks, moisture

- Significance: Ensures proper fiber distribution during production

Weight per Unit Area (g/m²)

- Purpose: Measure fabric weight

- Significance: Related to laminate strength and resin absorption

Moisture Control

- Purpose: Measure humidity in the fiber

- Significance: High moisture hinders resin bonding and weakens lamination

Tex (Linear Density)

- Purpose: Determine yarn density (g/1000 m)

- Significance: Critical for mechanical performance calculations

Loss on Ignition

- Purpose: Measure coating material on fibers

- Significance: Directly affects resin bonding quality

Note: Resin–fiber compatibility directly influences GRP pipe stiffness, flexibility, and chemical resistance. Therefore, every raw material batch is thoroughly tested and approved prior to production.

3. Sand Analyses

Sand is a key raw material in GRP pipe production, directly affecting strength and quality. Regular analyses at our Malatya CTP facility include:

Sieve Analysis

- Purpose: Determine particle size distribution

- Significance: Uniform grains ensure better resin bonding

Turbidity Analysis

- Purpose: Measure fine and soluble particles

- Significance: High turbidity can negatively affect bonding

Loss on Ignition

- Purpose: Identify organic and volatile components

- Significance: Affects purity and resin compatibility

Moisture Measurement

- Purpose: Measure water content

- Significance: High moisture may hinder bonding and cause deformation during production

Note: Each parameter in sand analysis plays a critical role in ensuring the final product is strong, high quality, and long-lasting.

4. Gasket Tests

Gaskets used in various pipe systems are crucial for leak-proof performance. At our Malatya CTP Facility, gasket quality is verified with:

Dimensional Control

- Purpose: Ensure compliance with standard sizes

- Significance: Incorrect sizes can lead to leakage and system inefficiencies

Hardness Test

- Purpose: Measure material hardness

- Significance: Ensures durability and effective sealing over time