Our Quality Control System

A Quality Approach Beyond Standards

At Kuzeyboru, we believe the foundation of long-lasting and reliable solutions in infrastructure and superstructure projects lies in a strong understanding of quality. For us, quality is not just a goal—it is the core of our production culture. Every product we manufacture embodies a fusion of values, including sustainability, customer satisfaction, engineering precision, and environmental responsibility.

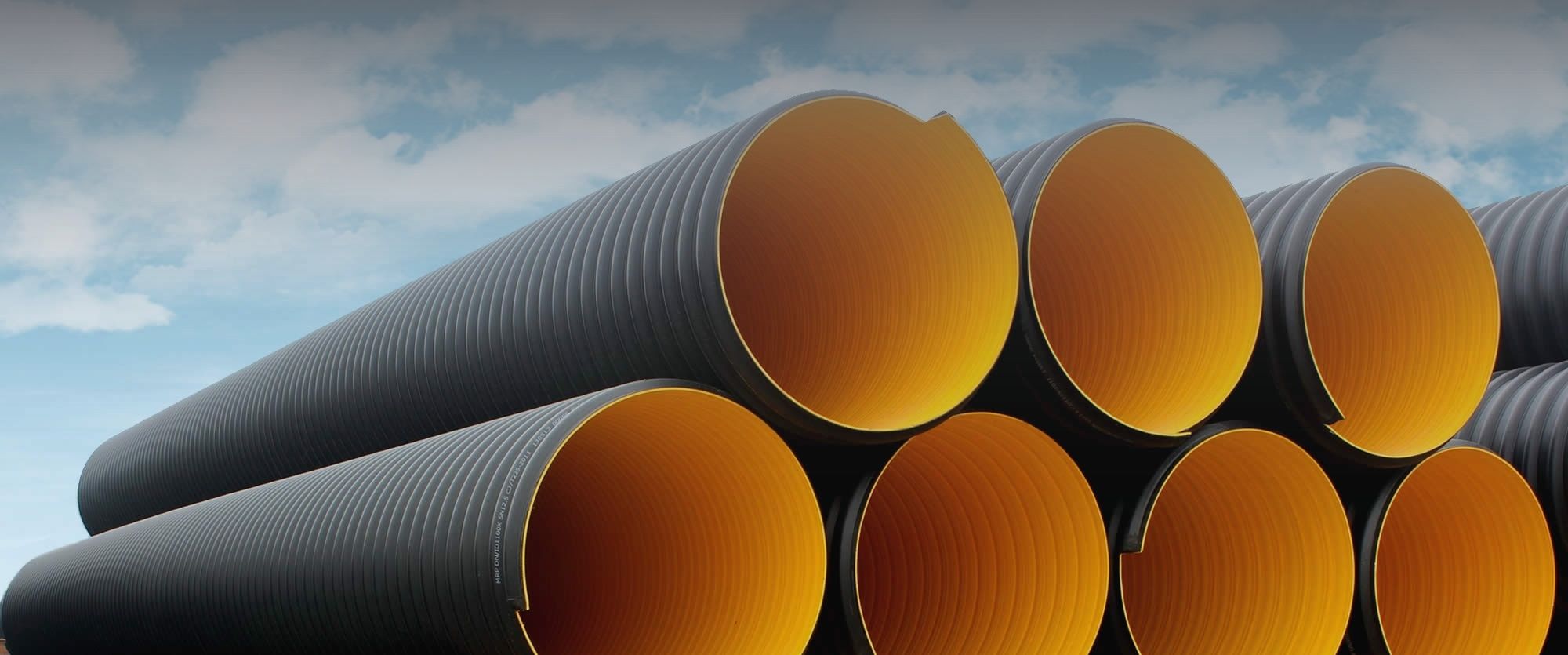

In our laboratories located in Aksaray and Malatya, our pipes are tested using the most advanced technologies, in full compliance with national and international standards. Our CTP, HDPE, Corrugated, PP-R, and other product groups are subjected to mechanical, chemical, and environmental resistance tests—ensuring proven performance in every application.

Each stage of the production process is digitally monitored, measured, and recorded through our automated quality control systems. From raw material entry to the final product, our digital traceability and reporting infrastructure help us minimize human error and maximize efficiency.

For us, testing is not just a routine procedure—it is the embodiment of our engineering strength, our unwavering commitment to quality, and the promise we make with every product we deliver.

Digitalized Quality Processes

Ensuring excellence in digital quality control requires meticulous monitoring, control, and reporting at every stage of production.

We apply this principle across our various manufacturing lines—CTP pipes, corrugated pipes, HDPE100, PE100-RC, PE80 pipes, PP-R and PP-RC pipes, and PP fittings produced through injection molding—using advanced digital systems to enhance efficiency and minimize errors.

This process is carried out in five key stages:

1. Incoming Quality Control (Pre-Production)

Material Quality Monitoring

Before production begins, all materials we use—such as fiberglass, resin, polyethylene, and polypropylene—are subjected to compatibility tests through our digital quality control systems. The chemical and physical properties of each material are measured using digital sensors and analytical devices, then recorded in our database. We also verify their compliance with standards like ASTM and TS through digital validation.

Incoming Control Reports

For every production batch, we generate digital incoming quality control reports. These documents include everything from supplier information to detailed quality parameters and are securely archived in digital format.

Digital Inventory Management

All materials are digitally tracked, allowing instant access to usage quantities, supplier data, and quality reports for each batch.

2. In-Process Quality Control

Monitoring of Temperature, Pressure, and Speed

In the production of GRP, HDPE, and PE pipes, we monitor critical parameters—such as extrusion temperature, pressure, speed, and humidity—in real-time using digital sensors. If any deviations occur, the system immediately generates warnings.

Filament Winding Method (GRP Pipes)

In GRP pipe production, the alignment of the winding and the bond strength between layers are closely controlled by digital systems. Ultrasonic thickness gauges and layer placement technologies allow us to monitor the thickness of every pipe with high precision.

Process Error Detection

Surface cracks, dimensional deviations, and material inconsistencies that may occur during production are instantly detected by digital sensors. Parameters like pipe diameter and straightness are monitored using laser scanners and visual inspection systems, allowing immediate intervention when necessary.

Dimensional and Shape Accuracy

We use laser scanners and digital measuring devices to check the dimensional integrity of our pipes—including diameter, length, and wall thickness. These measurements are recorded in our system, and digital certificates are created for each product.

Leak Testing

HDPE and PE pipes undergo water-based leak tests at specific pressure levels using digital pressure testing systems.

Mechanical and Chemical Testing

The tensile, torsional, and pressure resistance of pipe materials is measured using advanced digital testing equipment. Chemical composition is also analyzed using digital tools to ensure conformity.

Final Visual Inspection

Surface quality of PP-R and PP-RC pipes is assessed using high-resolution cameras and image processing software. Any surface defect triggers an automatic system alert for corrective action.

Database Management

We archive all production and quality control data on digital platforms. This ensures that every detail—from raw materials to final tests—is traceable in a single digital file for each product.

Digital Reporting and Certification

All production processes are monitored in real time via digital systems. This continuous data stream enables the earliest possible error detection and rapid response.

Digital Reporting and Certification

Digital quality control reports are created for every product and shared with customers, along with comprehensive test results and digital certificates for each production batch.

Infrastructure Production

During the production of all product groups, we digitally monitor and control critical parameters such as diameter, length, and surface quality with precision.

Superstructure Production

We also manage the quality control processes of pipes used in superstructure projects through digital platforms. For large-scale projects, we provide all quality certificates and test reports in digital format.

Thanks to this digital quality control approach, we ensure complete accuracy, high traceability, and fast response capabilities at every stage of production. The data we gather throughout the process provides a strong foundation for continuous quality improvement and production optimization.