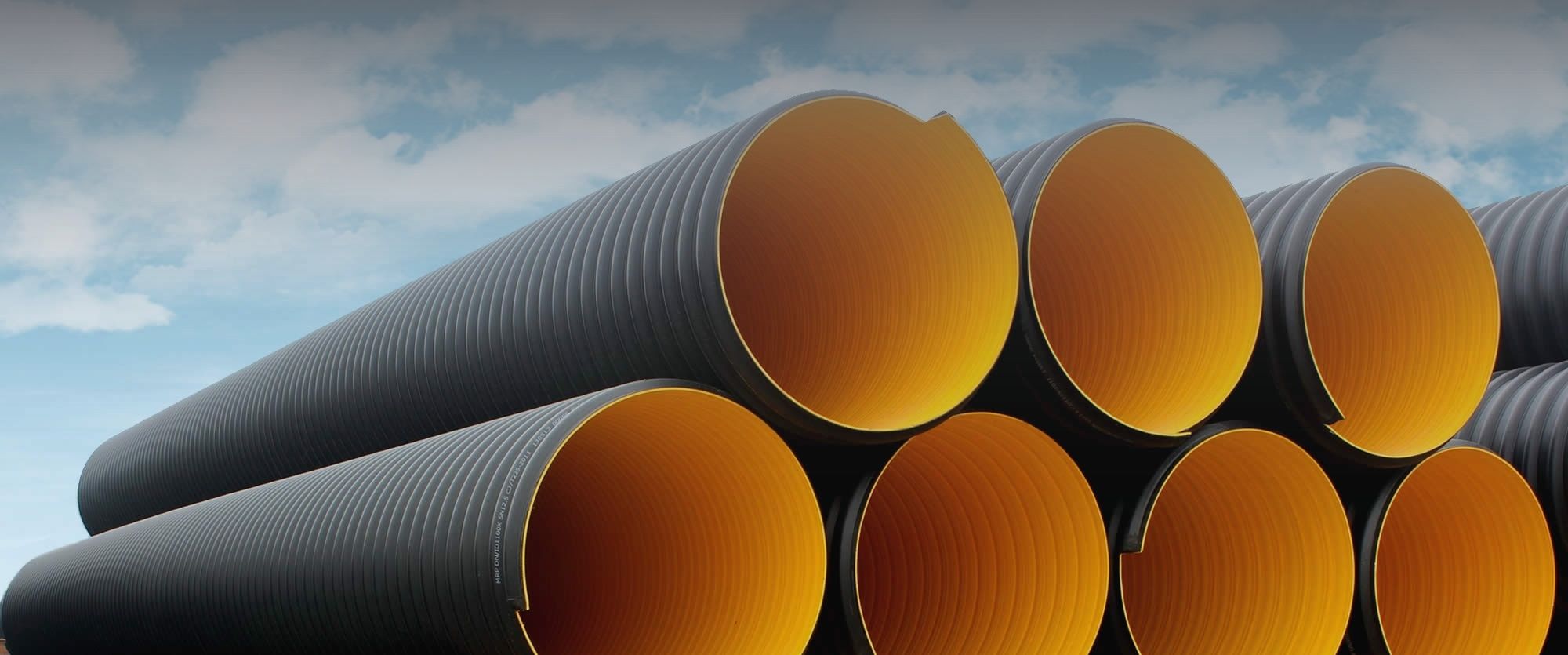

Steel Reinforced

Corrugated Pipe

Kuzeyboru Steel Reinforced Spiral Corrugated Pipes are advanced infrastructure solutions combining high-density polyethylene (HDPE) with a steel-reinforced outer structure, offering superior durability and strength. These pipes merge the structural power of steel with the flexibility of polyethylene to deliver maximum performance even under challenging field conditions.

Manufactured on state-of-the-art production lines, our steel reinforced pipes are available in nominal diameters ranging from 800 mm to 2400 mm, with ring stiffness values from SN4 up to SN16. This combination ensures high pressure resistance and long service life.

A steel reinforced corrugated pipe consists of three layers: an inner layer and an outer layer made of high-density polyethylene (HDPE), and a middle layer formed by “V”-shaped steel strips. Before shaping, the steel strips are coated with a special polyethylene adhesive resin to ensure excellent bonding.

The inner layer is created by HDPE extrusion and wrapping, which, combined with resin-coated steel, provides exceptional durability. The resin and polyethylene coating protect the steel against corrosion, making Kuzeyboru’s steel reinforced corrugated pipe unique with its high strength advantage.

Compared to traditional corrugated pipes, these reinforced pipes feature a stronger structure, offering long-lasting performance under heavy loads and difficult soil conditions. Thanks to their flexible and lightweight design, they provide ease of transport and installation, while high ring stiffness values ensure superior resistance.

Kuzeyboru Steel-Reinforced Corrugated Pipe is produced in a wide diameter range from 800 mm to 2400 mm with ring stiffness classes SN4, SN8, SN10, SN12.5 and SN16. Thanks to its durability, long service life and high performance, it provides a reliable and economical solution for infrastructure projects.

With its high strength and cost advantage, Kuzeyboru offers the most efficient and secure pipe solutions for your projects.

Steel Reinforced Corrugated Pipes by Kuzeyboru: Strengthening Your Project

Our Steel Reinforced Corrugated Pipes, specially manufactured for your project, are made from polyethylene raw material. They are produced to be compatible with electrofusion welding. With their high strength and durability, Steel Reinforced Pipes can be safely used in special and demanding projects. The High-Density Polyethylene (HDPE) raw material used in our Steel Reinforced Corrugated Pipes is also suitable for hygienic transport. These pipes can be preferred for the conveyance or storage of food, clean water, and similar applications.

Materials Used

Steel Raw Material:

DKP DC01 Coil Sheet Steel

DKP DC01 is a cold-rolled, low-carbon steel sheet known for its high surface quality, excellent workability, and ease of shaping, cutting, and drilling. Widely used in manufacturing, it is ideal for this application.

Adhesive Resin

Modified polyethylene-based adhesive resin containing TPE (thermoplastic elastomer) with maleic anhydride grafting.

Designed specifically for HDPE steel reinforced corrugated pipe applications, ensuring superior bonding between polyethylene layers and steel strips.

Exhibits high adhesion strength, thermal stability, flexibility, and aging resistance, preventing delamination of layers.

Technical Features

- Manufactured using HDPE raw materials, ensuring durability and long life.

- Suitable for electrofusion welding, enabling secure joints for demanding projects.

- Food-grade HDPE used, making pipes suitable for potable water and food transportation.

- Provides leak-proof and robust connections, ensuring safe installation.

- High resistance to heavy loads and harsh soil conditions.

- Available in sizes from 800 mm to 2400 mm diameter, with ring stiffness from SN4 to SN16.

- Resistant to acidic and basic environments.

- Facilitates transportation, installation, and laying processes with a lightweight structure.

- Manufactured to meet high-quality standards with over 50 years of expected service life.

Nominal Diameters of Steel Reinforced Spiral Corrugated Pipes

| Nominal size (mm) | Inside Diameter (mm) | Outside Diameter (mm) | Pitch (mm) | Minimum Pipe Stiffness (MPa) |

| 800 | 813 | 891,8 | 108 | 0,4 |

| 900 | 914 | 1000,8 | 124 | 0,4 |

| 1000 | 1016 | 1198,9 | 169,9 | 0,4 |

| 1200 | 1219 | 1432,1 | 205 | 0,4 |

| 1400 | 1372 | 1603,2 | 224,8 | 0,4 |

| 1600 | 1676 | 1940,6 | 235 | 0,4 |

| 1800 | 1829 | 2107,7 | 235 | 0,4 |

| 2000 | 2032 | 2317,8 | 235 | 0,4 |

| 2200 | 2235 | 2529,2 | 235 | 0,4 |

| 2400 | 2438 | 2732,6 | 235 | 0,4 |

| Note: Custom intermediate diameters can be produced upon customer or project request. | ||||

| Nominal size (mm) | Ring stiffness values (kN/m²) | ||||

| DN | SN4 | SN8 | SN10 | SN12,5 | SN16 |

| 800 | + | + | + | + | + |

| 900 | + | + | + | + | + |

| 1000 | + | + | + | + | + |

| 1200 | + | + | + | + | + |

| 1400 | + | + | + | + | + |

| 1600 | + | + | + | + | + |

| 1800 | + | + | + | + | – |

| 2000 | + | + | + | + | – |

| 2200 | + | + | + | + | – |

| 2400 | + | + | + | + | – |

Pricing Information for Steel Reinforced Corrugated Pipes

Prices vary depending on diameter, ring stiffness class (SN4 to SN16), production processes, and specific project technical requirements. Steel reinforced pipes provide cost-effective solutions with high strength and durability. Their lightweight nature lowers transport costs, and electrofusion welding simplifies installation, reducing labor expenses.

Pricing depends on size and technical specifications. Kuzeyboru offers high-quality production, competitive pricing, and a wide product range tailored to your project needs. For the latest price lists and detailed information, please contact Kuzeyboru or request a quotation.

Use of Steel Reinforced Corrugated Pipes

Steel reinforced corrugated pipes have a wide range of applications including sewage systems, wastewater and water discharge, drinking water, industrial and process pipelines, stormwater, seawater, water treatment systems, drainage collectors and outlet pipes, cooling water, pipeline repair, pipe renewal, water tanks, hydroelectric power plants (HPP), dams, and culverts.

Main usage areas of steel reinforced corrugated pipes include:

- Sewage Systems: Safely used in wastewater and sewage lines due to their high strength.

- Stormwater Drainage: Durable and long-lasting solution for efficient water discharge during heavy rainfall.

- Industrial Wastewater Lines: Suitable for factories and industrial facilities because of their high chemical resistance.

- Clean Water Transmission Lines: Safe for drinking water and other fluid conveyance with HDPE raw material compliant with health standards.

- Agricultural Irrigation Systems: Ensures efficient water transportation in large-scale irrigation projects.

- Hydroelectric Power Plants (HPP): Provides high-pressure resistance in water transfer and energy production processes.

- Seawater Discharge and Transfer Lines: Offers superior protection against saltwater and corrosive substances.

- Culverts and Underpasses: Durable infrastructure solution for roads, bridges, and railway crossings.

- Underground and Infrastructure Systems: Long-term usage advantage in telecommunication and electrical cable protection systems.

Advantages of Steel Reinforced Corrugated Pipes

Steel reinforced corrugated pipes are among the most durable pipe solutions preferred in infrastructure projects due to their high strength, long-lasting structure, and ease of installation. Joined by electrofusion welding, they guarantee leak-tight connections and save time during installation.

Key advantages of steel reinforced corrugated pipes include:

- High pressure resistance thanks to steel rib reinforcement.

- Resistance to impacts, ground movements, and UV rays, ensuring longevity under harsh weather conditions.

- High corrosion and chemical resistance; they do not rust or decay.

- Lightweight and flexible structure makes transport and installation easier.

- Can be nested and stacked to save storage space.

- Long service life, usable up to 50 years.

- Electrofusion welding allows fast, secure, and leak-proof joining.

- Suitable for tight excavation areas, offering flexibility in infrastructure projects.

- No separation or breakage at joints under pressure.

- Smooth inner surface ensures high flow velocity without sediment or clogging.

- Excellent welding properties provide leak-free, long-term safe use.

- Resistant to chemical and biological substances; environmentally friendly solution.

With superior technical features and durability, steel reinforced corrugated pipes stand out as reliable, economical, and eco-friendly choices in infrastructure projects.

Thanks to their lightweight and durable structure, steel reinforced corrugated pipes are easy to transport, providing significant advantages during installation. Produced in standard 6-meter lengths, they can be laid safely without risk of cracking or breaking due to their high strength. Electrofusion welding ensures full leak tightness, maximizing efficiency in infrastructure projects.

This installation method offers quick and reliable assembly, saving time and labor costs. Its flexible design allows easy application even in narrow trench areas, speeding up and optimizing the laying process. The pipes’ durability and long service life make them a reliable and economical solution for infrastructure needs.

Steel reinforced corrugated pipes are assembled using the electrofusion joining method, which provides high strength and long-lasting performance. The pipes are specially designed and manufactured to match the dimensions and diameters required for steel reinforcement, ensuring flawless joints.

Electrofusion Welding Joining

The electrofusion welding process for steel reinforced corrugated pipes must be carefully applied to ensure full leak tightness and durability. Important steps include:

- Welding must be performed at temperatures above 5°C.

- Pipes must be joined end-to-end with minimal gap.

- An electrofusion (EF) tape is wrapped around the joint and tightened with a strap.

- Welding time and parameters must be set on the welding machine; leak tests are done after welding.

- The EF tape terminals are connected to the welding machine’s current clamps.

- Fusion occurs between 190-200°C with current applied for 6-15 minutes depending on weather conditions.

- Pipes remain immobile during a 15-20 minute cooling phase.

- The weld area is filled after cooling, and pipes must not be moved until the filler hardens.

The most critical factor for successful welding is the correct equipment. Kuzeyboru’s Pipe Welding Machine provides high efficiency and reliability for steel reinforced corrugated pipe joining, maximizing performance in your projects.

These pipes, produced to match exact diameters and sizes, offer fast, safe assembly with high strength, durability, and leak-tightness in infrastructure works.

Storage of Steel Reinforced Pipes

Steel reinforced corrugated pipes are widely preferred for infrastructure projects due to their high strength and long lifespan. Proper storage is crucial to maintain their quality and performance. Incorrect storage, especially not matching pipe sizes and diameters, can cause deformation and structural damage.

Storage Guidelines

- Pipes can be stored indefinitely without exposure to sunlight.

- For long-term indoor storage, temperature should be controlled.

- Outdoor stored pipes should ideally be used within one year.

- Extreme temperatures may alter pipe properties.

- Storage areas must be flat and clean, free from sharp or hard objects to avoid damage.

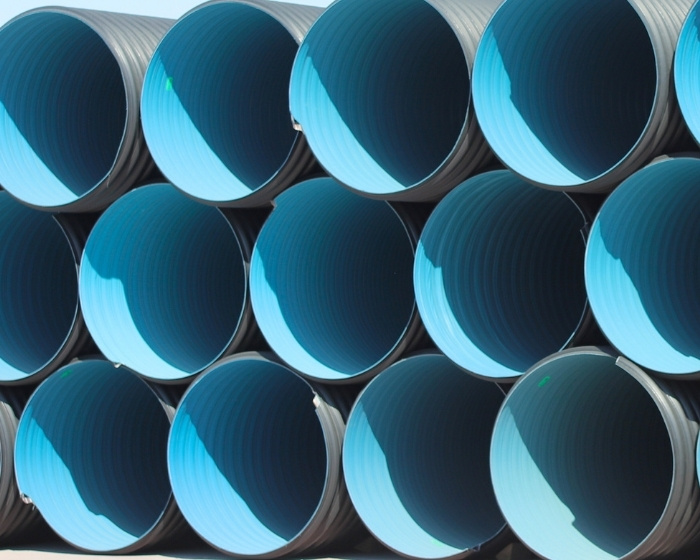

Stacking Rules

- Pipes up to 1000 mm diameter should be stacked in a maximum of two rows.

- Pipes 1000 mm and above should be stored in a single row.

- Nested pipes should not be stacked on top of each other to prevent deformation.

Correct storage techniques preserve pipe strength and lifespan, ensuring maximum efficiency in projects.

Loading and Transportation

Thanks to their lightweight and durable structure, steel reinforced corrugated pipes are easy to transport. Their ability to nest inside one another saves space and reduces transportation costs. However, specific rules must be followed for safe loading and transportation:

- Pipes can be nested according to their size and diameter, optimizing logistics.

- Custom lengths ease project-specific transport planning.

- Pipe ends are sensitive and must be protected against impacts.

- Vehicle side supports should be positioned to avoid damaging pipes, and protective measures taken.

- Pipes must not be dragged on the ground; use forklifts or cranes for handling.

- Transport vehicles should be chosen based on pipe diameters.

- Stacking arrangements must prevent deformation.

- Necessary safety precautions must be observed during transportation to ensure long service life.

For detailed technical advice on loading and transport, please contact us.

They provide superior resistance to heavy loads, harsh weather, and chemicals due to high ring stiffness (SN4, SN8, SN10, SN12.5, SN16) and steel reinforcement. They offer a service life of up to 50 years, making them reliable for long-term infrastructure projects.

Thanks to their lightweight and flexibility, they are easy to transport and apply even in narrow trenches. Electrofusion welding ensures leak tightness, and proper bedding materials increase pipe strength during installation.

Joining is performed using electrofusion welding. Resistance couplers create flawless, leak-proof joints, enabling fast, safe, and cost-effective installation.