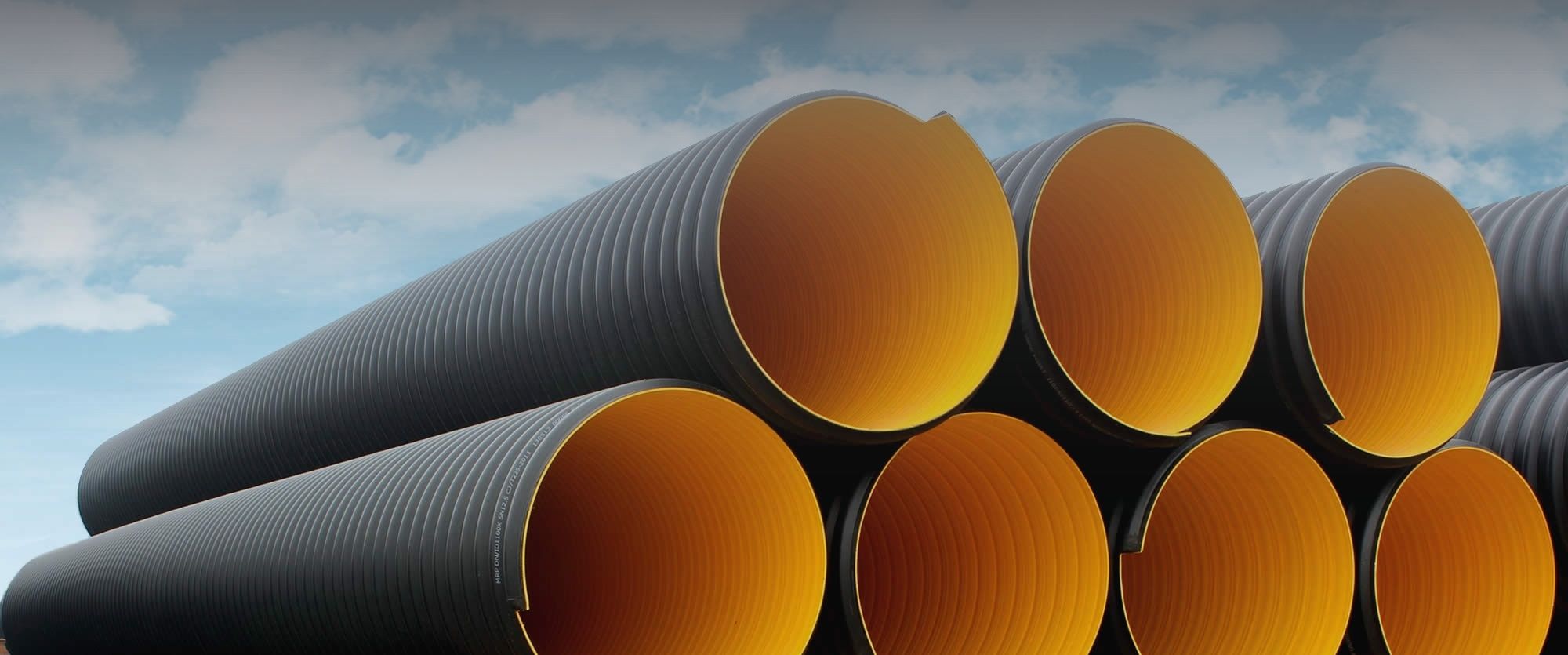

Our corrugated pipes combine high strength, flexibility, and chemical resistance, making them indispensable components of modern infrastructure projects. Their lightweight design allows for easy transportation and practical installation. Widely used in sewage, drainage, and stormwater discharge systems, these pipes demonstrate excellent durability against abrasion and external impacts. Environmentally friendly and long-lasting, corrugated pipes offer cost advantages while providing safe and efficient fluid conveyance solutions. Kuzeyboru corrugated pipe systems are manufactured from polyethylene (PE) raw material in compliance with TS EN 13476–3 standards. They are produced with ring stiffness values ranging from SN4 to SN16 and available in nominal diameters DN100, DN150, DN200, DN300, DN400, DN500, DN600, DN800, and DN1000, each 6 meters long with socketed ends.

Kuzeyboru is a brand that stands out in the infrastructure sector with its innovative solutions and high-quality products. One of the most significant reflections of this success, corrugated pipes combine the brand’s engineering expertise to make a difference both technically and performance-wise. Manufactured from high-density polyethylene (HDPE) raw material, Kuzeyboru corrugated pipes raise industry standards in terms of durability, flexibility, and longevity. Thanks to Kuzeyboru’s production technology, the corrugated pipes possess high ring stiffness and demonstrate excellent resistance to high underground loads. At the same time, the smooth structure of the inner surface increases flow efficiency and ensures minimal energy loss in the system. Its flexible structure adapts to ground movements; this transforms Kuzeyboru products into not only a strong but also a safe infrastructure solution.

Our brand’s meticulous quality control processes guarantee that each corrugated pipe complies with national and international standards, while enabling the products to operate for many years without requiring maintenance. Thanks to their light weight and practical installation systems, time and labor are saved, and their recyclable nature makes them safely usable in eco-friendly projects.

Kuzeyboru’s R&D-focused approach and sustainable production philosophy transform corrugated pipes from merely an infrastructure material into a long-lasting, cost-effective, and environmentally responsible system solution. In this respect, Kuzeyboru not only applies corrugated pipe technology but also advances it, addressing tomorrow’s infrastructure needs today.

A Step Ahead in Technology: 100% Leak-Proof Corrugated Pipe System

Kuzeyboru pioneered the integration of its proprietary Full Seal (FS System) technology into corrugated pipes, ensuring years of trouble-free underground operation.

With enhanced FS System features, absolute leak-tightness is guaranteed even at joint connections, maximizing the safety of your infrastructure projects. Kuzeyboru corrugated pipes add value through high performance, long service life, and environmental protection.

Key Technical and Structural Features of Corrugated Pipes:

- Special trapezoidal profile provides high resistance to soil and traffic loads.

- Made from HDPE to enhance flexibility and strength.

- Absorbs shocks and load changes elastically, returning to original form without damage.

- Suitable for use in temperatures from -50°C to +60°C.

- Requires minimal maintenance and can be cut easily with saws or jigsaws.

- Damaged sections can be repaired by opening and using a sliding sleeve.

- No material loss occurs during installation.

- High chemical resistance, abrasion-proof, and long-lasting.

- Prevents blockage by minimizing sediment and deposits.

- Long-term safe use ensured by high resistance to external loads.

- Nested stacking saves transportation space, time, and costs.

Kuzeyboru Corrugated Pipes

Where Durability Meets Engineering Excellence

Kuzeyboru corrugated pipes are reliable solutions that deliver superior performance for demanding infrastructure projects. Developed with Kuzeyboru’s advanced engineering capabilities and quality-focused production approach, these corrugated pipes provide long service life thanks to their durable construction. They stand out with exceptional resistance to chemicals, abrasion, and corrosion. Their flexible, lightweight design makes them easy to install in the field, accelerating the assembly process and saving labor.

Continuously enhanced by Kuzeyboru’s R&D strength, these systems demonstrate maximum durability even under varied ground conditions, addressing a wide range of applications. They are confidently chosen across everything from infrastructure and industrial facilities to agricultural and urban projects. Produced with the Kuzeyboru advantage, corrugated pipes are not just an infrastructure product but the foundation of safe and sustainable projects.

Common Application Areas:

- Sewage and Wastewater Systems

- Stormwater and Snowmelt Drainage Systems

- Drainage Systems

- Industrial Wastewater Systems

- Gravity (Non-Pressure) Fluid Transport

- Chemical and Biological Waste Transport

Kuzeyboru corrugated pipes provide durable and cost-effective solutions for both infrastructure and industrial projects.

Advantages of Kuzeyboru Corrugated Pipes

Kuzeyboru corrugated pipes offer maximum safety with their flexible and durable structure. Resistant to traffic loads, impact, earthquakes, and soil shifts, their elasticity prevents breakage by adapting shape under heavy loads, even in gravelly soils.

The full-seal gasket system used in installation ensures zero leakage, protecting not only pipeline efficiency but also the environment. The abrasion-resistant surface prevents punctures and contamination of groundwater and soil. Made from polyethylene, they exhibit superior corrosion resistance.If your projects demand leak-tightness, flexibility, and durability, Kuzeyboru corrugated pipes offered in various diameters and connection options are the ideal choice.

What Makes Corrugated Pipes Different?

Corrugated pipes stand out as efficient pipe systems in infrastructure projects, combining durability, lightness, and cost efficiency. Kuzeyboru corrugated pipes provide a long-lasting, flexible, and high-performance solution with PE material. Key differentiators:

- Guaranteed corrosion and external impact resistance for at least 50 years, with a service life of up to 100 years.

- Smooth inner surface reduces flow resistance, increasing liquid velocity and fill ratio.

- Higher flow capacity often allows selecting one size smaller diameter, reducing total project cost.

- Generally cheaper than rigid pipes, requiring fewer fittings and providing cost-effectiveness.

- High resistance to chemicals, abrasion, and environmental factors minimizes maintenance needs over time.

Corrugated pipes are the perfect choice for modern infrastructure projects thanks to their cost advantages, longevity, and ease of installation.

Kuzeyboru stands out as a brand known for quality, reliability, and engineering excellence in infrastructure systems, leading the sector with its specially developed varieties of corrugated pipes tailored for diverse needs. Produced from HDPE raw material, these pipes feature high strength, chemical resistance, flexibility, and long service life, offering maximum efficiency and safety to projects thanks to Kuzeyboru’s superior production quality.

Corrugated Pipes

Kuzeyboru’s classic corrugated pipes are safely used in infrastructure projects with their high rib strength and smooth inner surface. Their corrosion-resistant structure, complete leak-tightness, and service life of up to 50 years make these pipes ideal solutions for sewage, stormwater, and drainage systems. Their lightweight nature allows for easy transportation and installation, saving time and cost. Kuzeyboru manufactures corrugated pipes with socket or without, ranging from nominal diameters of 100 mm to 1000 mm, according to the TS EN 13476-3 standard.

Steel Reinforced Corrugated Pipes

Kuzeyboru’s steel reinforced corrugated pipes are produced by combining polyethylene and steel in perfect harmony. The spiral steel reinforcements strengthen the structure, providing outstanding mechanical durability. These pipes are preferred especially in large-diameter water transmission lines, industrial systems under heavy loads, and infrastructure projects. Despite being lightweight, their load capacity is very high, making them both economical and long-lasting solutions. Kuzeyboru manufactures steel reinforced corrugated pipes in diameters from 800 mm to 2400 mm according to TSEK-2 standards.

Perforated (Slotted) Corrugated Pipes

Kuzeyboru’s perforated pipes offer ideal solutions for areas requiring groundwater drainage. Thanks to specially designed holes on the pipe surface, excess water in the soil is easily collected and discharged. Used in agricultural fields, highway shoulders, building foundations, and sports grounds, these pipes maintain soil stability. With Kuzeyboru’s precise perforation technology, high efficiency is achieved while minimizing system blockages. Perforated pipes are produced in nominal diameters from 100 mm to 1000 mm for standard corrugated pipes and 800 mm to 2400 mm for steel reinforced corrugated pipes, according to customer demands.

Geotextile Wrapped Corrugated Pipes

Developed for efficient drainage systems, Kuzeyboru’s geotextile wrapped pipes allow only water to pass through via the filter fabric covering, preventing soil and particles from entering the pipe. This reduces clogging risks and minimizes maintenance needs. They provide long-lasting and effective solutions for demanding applications such as agriculture, highways, and foundation drainage.

At Kuzeyboru’s Corrugated Pipe Production Facility, established on a 162,336 m² area, we maintain our production activities with advanced technology infrastructure and high-quality standards. Our modern production lines carefully manufacture corrugated pipes and fittings in various diameters and sizes using the latest production techniques. With expertise gained in corrugated pipe manufacturing, we develop innovative, reliable, and durable solutions tailored to infrastructure projects. Our products stand out with high strength, resistance to environmental impacts, and sustainable performance. Thanks to our extensive product range, we serve not only projects in Turkey but also international markets, continuing as a strong global solution partner.

Corrugated pipes are produced from petroleum-derived high-density polyethylene (HDPE) and offer superior performance against harsh ground conditions. They provide high impermeability in water-saturated or acidic soils, preventing corrosion and contributing to the long service life of infrastructure systems.

Our production process manufactures pipes in various diameters and wall thicknesses, complying with international quality standards. Due to their lightweight and flexible structure, corrugated pipes are easy to install and also provide high impact resistance for safe use on site. These features make them especially preferred in sewage and drainage systems.

Our annual production capacity is approximately 55,000 tons. Our product range includes SN4-SN8 corrugated pipes from 100 mm to 1000 mm diameter and SN8-SN16 steel reinforced corrugated pipes from 800 mm to 2400 mm diameter. This broad and strong product portfolio allows us to make a difference in the sector with tailored solutions for infrastructure projects.

Kuzeyboru’s corrugated pipe fittings are high-quality connection elements that enable secure, leak-proof, and durable joining of corrugated pipes in infrastructure projects. While corrugated pipes can be easily connected via their integral sockets, flexible solutions such as corrugated couplers are also offered according to needs.

To ensure uninterrupted and efficient operation of infrastructure systems, various fittings with different functions are available:

- Corrugated Elbow: Used for angled turns in pipelines. Prevents flow loss and safely directs the fluid.

- Corrugated Reducer: Used where pipe diameter changes within the line. It ensures continuity by reducing or increasing diameter.

- Corrugated Y Piece: Used at branching points in the line. Regulates and directs flow.

- Corrugated C Piece: Prevents suction loss in sharp bends. Contributes to efficient and balanced system operation.

- Corrugated End Cap: Used to close pipe ends safely and leak-tight.

- Corrugated Tee: Allows three-way connections, effective for system expansions.

All Kuzeyboru corrugated pipe fittings are produced in compliance with international quality standards, offering high leak tightness and durability even under tough field conditions.

For choosing the right connection solutions for your infrastructure projects and detailed product information, click here.

Request a Quote

Three methods are used for joining Kuzeyboru corrugated pipes:

- Socket Gasket Joint

- Coupler Gasket Joint

- Electrofusion Welding with EF Band (Steel Spiral)

Coupler Gasket Joining Method for Corrugated Pipes

In joining corrugated pipes, a gasket is placed between two pipes without sockets using a coupler. The pipes are pushed into the coupler, completing the joint and ensuring leak tightness. This method, which offers high sealing and durability, is widely preferred in drainage, sewage, and stormwater systems.

Socket Gasket Joining Method

Socket gasket joining is a reliable and practical method used in infrastructure projects. After selecting a gasket appropriate to the pipe diameter, the gasket is placed on the socket part of the pipe and sealed by joining the socket and spigot. This method offers easy installation and sealing benefits and is commonly used in sewage, drainage, and stormwater systems.

Electrofusion Welding Joining

In joining steel reinforced corrugated pipes, pipes are aligned end-to-end on a flat, clean, and dry surface and wrapped circumferentially with an EF band, which is then tightened with a spanzet tool. Copper conductors at the ends of the EF band are connected to the welding machine’s current clamps, applying current between 190-200°C for 6-15 minutes depending on weather conditions. After welding, the pipes remain stationary for 15-20 minutes to cool down. Afterwards, the weld area is filled, and the pipes are kept immobile until the filler solidifies.

Koruge Boru Frequently Asked Questions about Corrugated Pipes

A corrugated pipe is a durable infrastructure pipe made from high-density polyethylene (HDPE) raw material with a ribbed outer surface and a smooth inner surface. Its flexible structure shows high resistance to heavy loads, chemicals, and environmental factors.

Corrugated pipes are used in sewage, drainage, stormwater drainage, and industrial wastewater conveyance systems. They offer lightweight and easy installation, saving both cost and time in infrastructure projects.

HDPE corrugated pipes are pipe systems made from High-Density Polyethylene (HDPE) material, resistant to corrosion and chemicals, with long service life and lightweight properties. Their flexible structure withstands earthquakes, landslides, and impacts.

Corrugated pipes are produced in diameters ranging from DN100 to DN2400. They are available with ring stiffness values of SN4, SN8, SN12, and SN16, depending on the application and project requirements. For example, a DN500 corrugated pipe has an inner diameter of 49.6 cm and an outer diameter of 58.2 cm. Smaller diameter pipes are preferred for building drainage and stormwater systems, while larger diameter pipes are used for sewage and industrial infrastructure projects.

A 500 nominal diameter corrugated pipe is produced with an inner diameter of 49.6 cm (496 mm) and an outer diameter of 58.2 cm (582 mm). Different diameters and ring stiffness options are available according to project needs.

Corrugated pipes are widely used in sewage lines, stormwater drainage systems, industrial wastewater projects, energy and telecommunications cable protection systems, and many other areas. Their durable structure makes them a reliable choice for both urban and rural infrastructure projects.